Achieve better outcomes and best-in-class performance with effective, efficient fluidic design.

Arcmed helps solve the world’s toughest diagnostic and analytical challenges. We simplify the design and build of top-performing instruments that exceed your fluidics quality and performance requirements.

Building diagnostic and analytical instruments can be complex when your business needs fluidics expertise. We draw from 120+ years of combined experience, working collaboratively alongside you to save time and overcome tough design obstacles that create delays.

We know how challenging custom instrument design can be—at least when you’re not an expert in the industry. Let us do the heavy lifting for you so you can move forward with complete confidence in your designs and their components.

Your business needs quick, easy access to a supply of fluidic parts. We design reliable, scalable, high-quality solutions with fast lead times on prototypes and dependable delivery on production assemblies.

Say goodbye to production delays and unreliable turnaround times. Leveraging our proven expertise and wide range of in-house capabilities, we can help ensure dependable delivery from start to finish across the entire instrument lifecycle.

Unlike vertically integrated competitors with a limited range of products, our experienced, responsive teams use a wide variety of configurable solutions to design around your organization’s unique challenges and needs.

Access to limited selections of standard off-the-shelf fluidic components and accessories will hold your projects back, which is why we offer a wide variety of configurations, giving you the flexibility to easily customize components for your application.

Access industry-leading products and services to supplement the design and manufacture of precise fluid handling components.

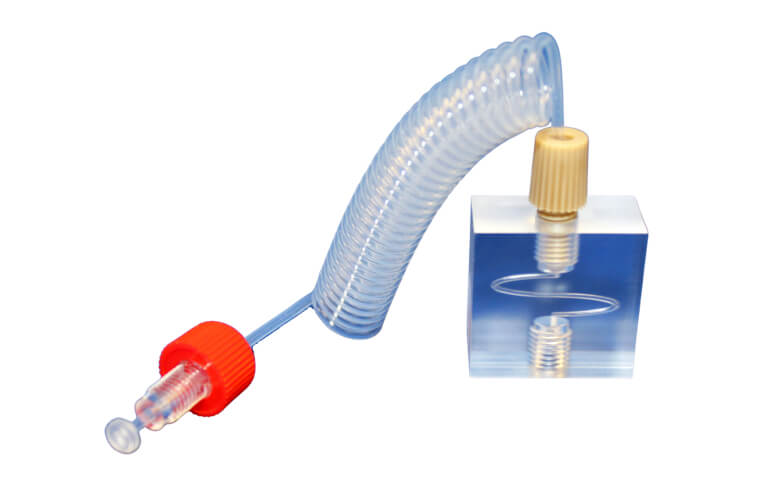

Connection components with tubing precisely transport fluids between fixtures and vessels throughout an instrument.

Learn More

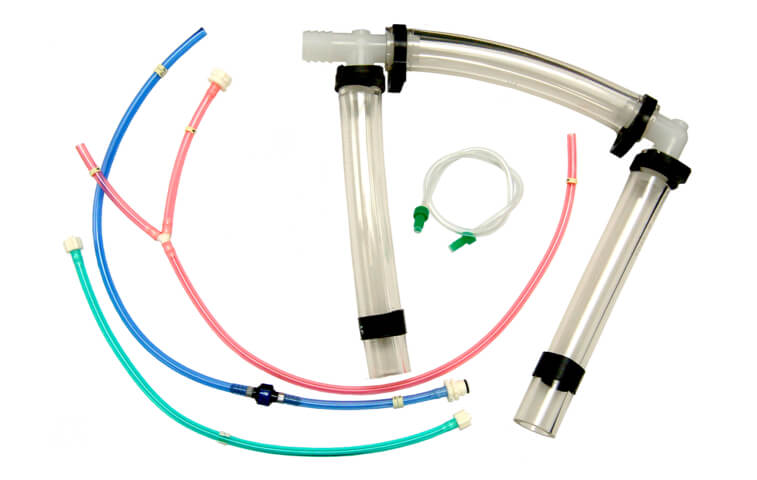

Pump and valve components with tubing are designed to control and direct fluids within an instrument system.

Learn More

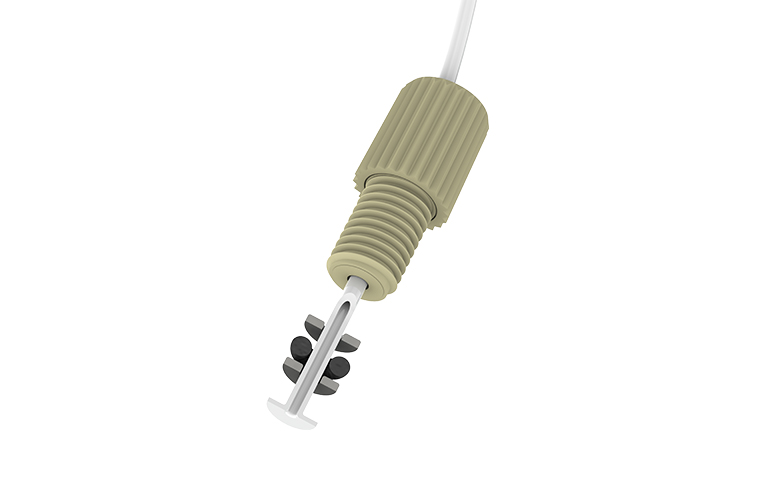

Probes, sensors, and heater components control transfer and temperature of samples, reagents, and waste fluids with minimal carryover.

Learn More

Manifolds reduce footprint, contamination, unmanageable wiring and tubing nests, and overall inventory costs and production time.

Learn More

Standard and custom fittings, connectors, adaptors, and tubing simplify the design process by creating compatible fluid transfer platforms.

Learn More

Labware services help achieve maximum performance for low- to mid-pressure liquid chromatography or flow chemistry applications.

Learn More

Standard and custom tubing assemblies are configured with a variety of labeling, printing, kitting, thermoforming, and extrusion options.

Learn More

Through our partnership services, we provide a dedicated, cross-functional team to solve your fluid handling and supply chain needs.

Learn MoreYou need a design and manufacturing partner you can trust — and that’s us. Learn all about the history, values, people, and news that define Arcmed.

Learn all about Arcmed: who we are, where we came from, and how we got to where we are today.

Find out which values drive us to deliver the best products and services possible for our customers.

Meet the Arcmed leadership, comprised of industry experts from Diba, Omnifit, Bio-chem Fluidics, and Halma.

Read the latest headlines about Arcmed and our wide range of best-in-class solutions and services.

Danbury, CT (Diba)

Boonton, NJ (Bio-Chem)

Shanghai, CN (HCG)

+86.21.6151.9061

Access best-in-class thought leadership on a wide range of topics around fluidics, diagnostic instrumentation, device manufacturing, and more.

© 2021 Arcmed