Our fittings, connectors, adapters, and tubing — simplified into compatible platforms.

Experience our innovative connection components grouped into a variety of assembly systems that ensure you achieve low carryover fluid transfer in your application.

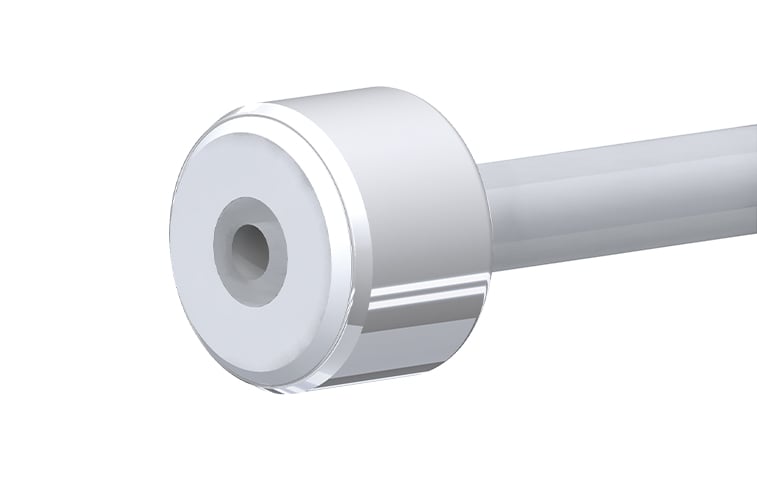

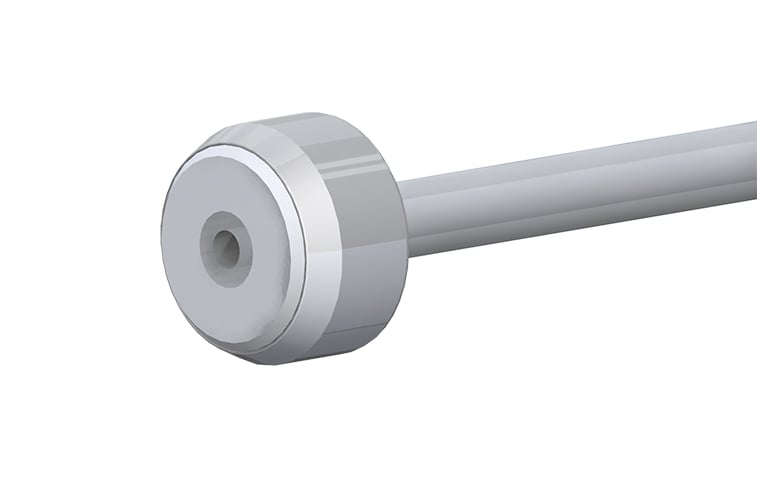

Typical thermoforming creates scoring and distortion of tubing that give particulates more surface to cling to, producing sample carryover. Our proprietary thermoforming process creates an inert, smooth surface with a flat-bottom, face seal.

When combined with our Click-N-Seal fittings, the flared tubing connection system produces a leak-free seal with only tube material in the fluid path. Flared tubing assemblies are available in a variety of configurations to adapt to your instrument.

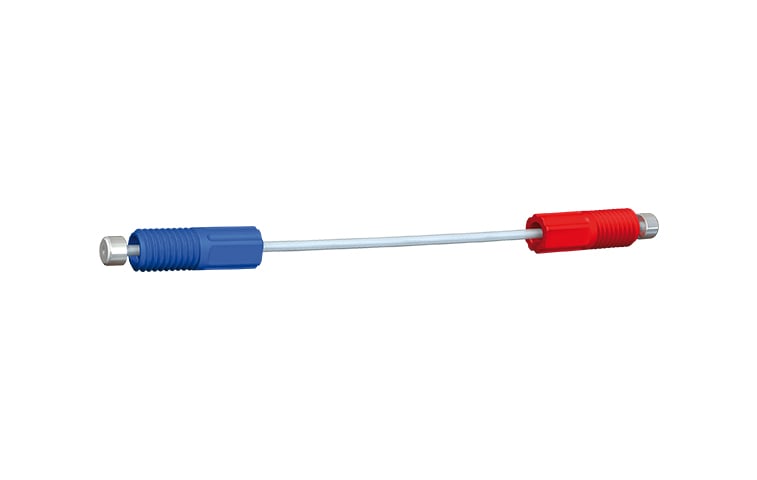

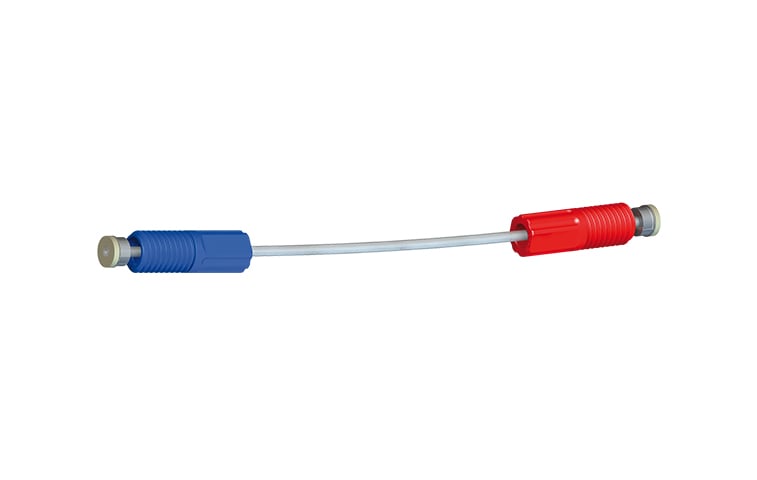

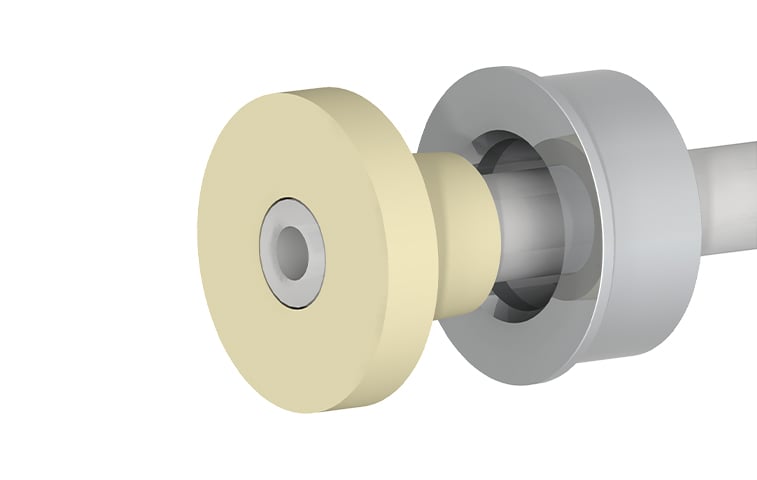

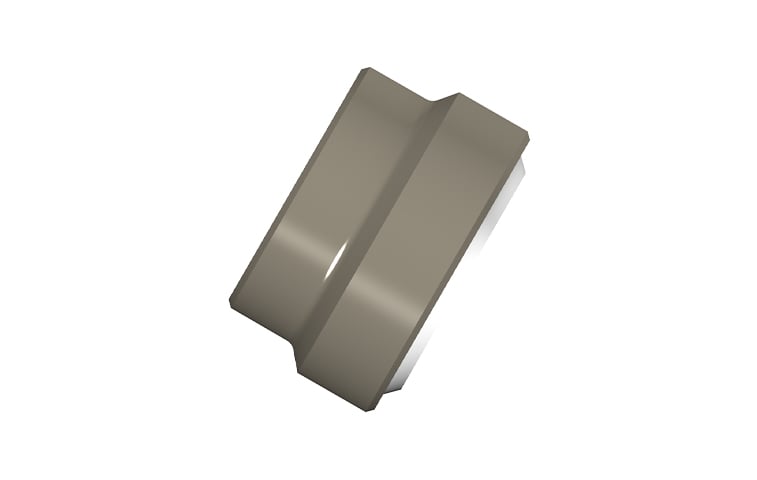

The Type P flangeless tube connection system incorporates a PTFE seal housed in a 316 stainless steel case. The Type P fitting system uses a one-piece ferrule, which fits permanently to the outside of the semirigid tubing.

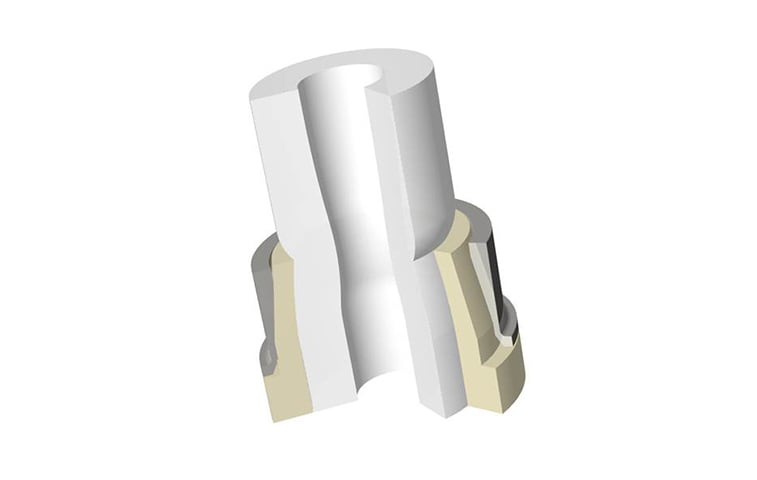

The Type S fitting system uses a two-piece ferrule that fits permanently to the outside of the tubing. Two-part ferrules consist of an inner PEEK sealing surface and a stainless steel lock ring, with only the inner portion in the fluid path.

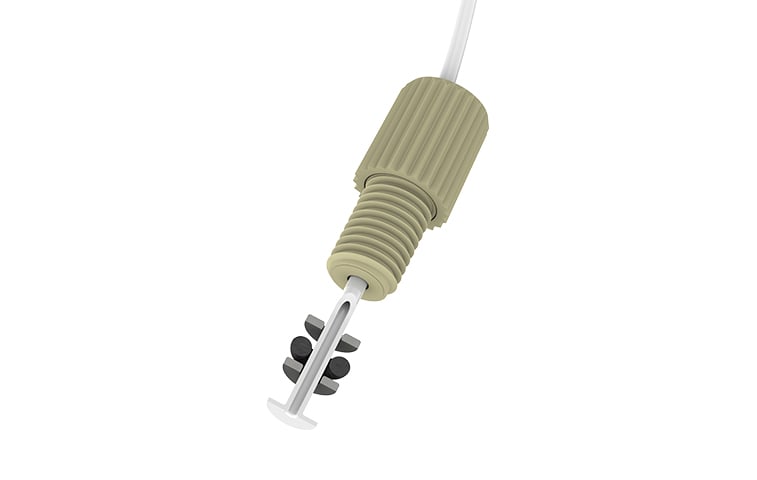

Gripper connection systems use a one-piece ferrule that fits permanently onto the outside of semirigid tubing. Ferrules have an outer stainless steel or PEEK casing and inner PTFE sealing face, ensuring that only PTFE is in the fluid path.

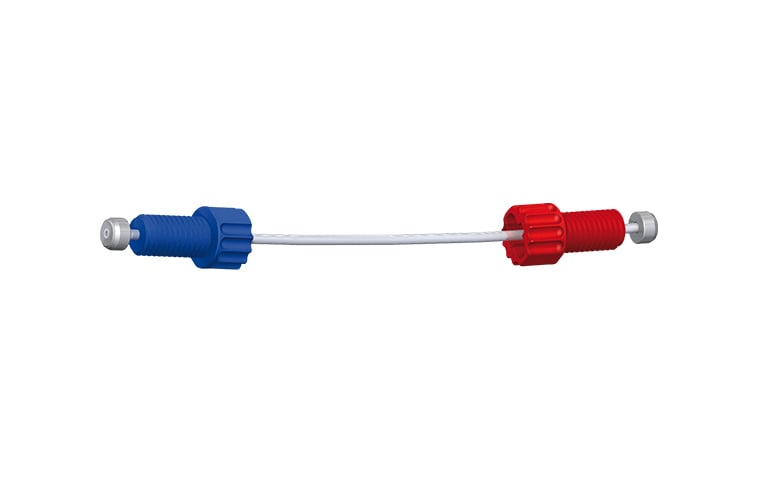

Inverted cones provide a reuseable, nonpermanent low-pressure connection with only the ETFE cone in the fluid path. A recess in the fitting houses the inverted cone, allowing maximum thread engagement with the port

Danbury, CT (Diba)

Boonton, NJ (Bio-Chem)

Shanghai, CN (HCG)

+86.21.6151.9061

Access best-in-class thought leadership on a wide range of topics around fluidics, diagnostic instrumentation, device manufacturing, and more.

© 2021 Arcmed